SmartCAT® inspections in France

Overview

In autumn 2024, Advanced Engineering Solutions (AES) was contracted by Suez to complete a series of non-destructive condition assessments on a ductile iron pipe in Brittany, North West, France. As a global leader in the water and waste management sectors, Suez wanted to conduct a proactive investigation into the condition of the water network around Brittany to determine if remedial actions will be needed to ensure the continued health of the network.

Scope of works

AES sent a small team over to France to carry out internal and external assessments on eight sections of buried ductile iron pipe ranging from 150mm to 300mm in diameter. The inspection areas at each location had already been excavated prior to their arrival.

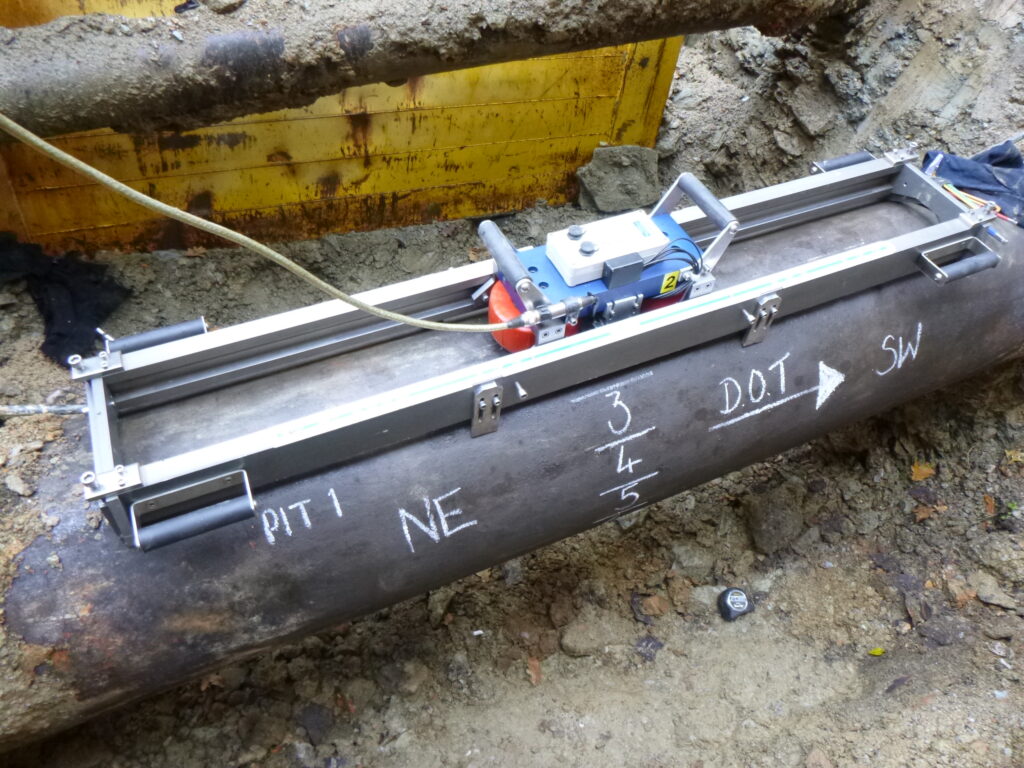

During the inspection, the team were looking for areas of pipe wall thinning, signs of corrosion and internal and external pipe wall defects. The team used AES’s patented SmartCAT® tool as a quick and non-invasive way to quantify the condition of the water main and predict its remaining service life. Data was also taken from the surrounding soil of the excavated pipe, to determine the corrosivity of the soil and how it will be affecting the pipe.

Due to the range of diameter pipes being inspected, both the standard SmartCAT® and the SmartCAT®360 were deployed.

Challenges

Mobilising the team and equipment to the overseas site posed a challenge. However, thanks to effective planning and execution, the team successfully arrived at the destination with their vanload of equipment intact and on schedule. This ensured that five consecutive days of inspections across eight locations commenced promptly.

Coordination between the AES site team and the French site team was not without challenge, due to the language barrier between them. However, both parties worked hard to communicate effectively and complete all the work, highlighting the expertise and professionalism of the technicians.

Outcome

All inspections were completed by the end of the five working day period and the data was sent back to AES to begin the analysis. For half of the inspected sites assessed to be in good condition, reinspection was recommended in ten years to monitor and reassess the projected service life. For the remaining sites, which were found to be in fair or poor condition, additional inspections further along the pipeline were advised to determine the extent to which other sections may be deteriorating at a similar rate.

Click here to find out more about SmartCAT®.