SmartCAT®

REDUCING PIPE REPLACEMENT COSTS THROUGH CONDITION ASSESSMENT

Pipe failure is not only expensive, there’s also reputation damage to consider alongside not achieving your performance commitments should failures lead to an interruption to customer water supply.

Pipe condition assessment helps you as a water company to understand the condition of your pipes and to minimise replacement costs through detailed insight. And, whilst there are multiple pipeline condition assessment technologies available, our SmartCAT® tool is proven to provide the highest level of internal and external pipe condition information.

SMARTCAT® HELPS YOU MAKE CONFIDENT DECISIONS ON PIPE REPLACEMENT

- Finds internal and external defects

- Non-intrusive

- Patented magnetic flux technology

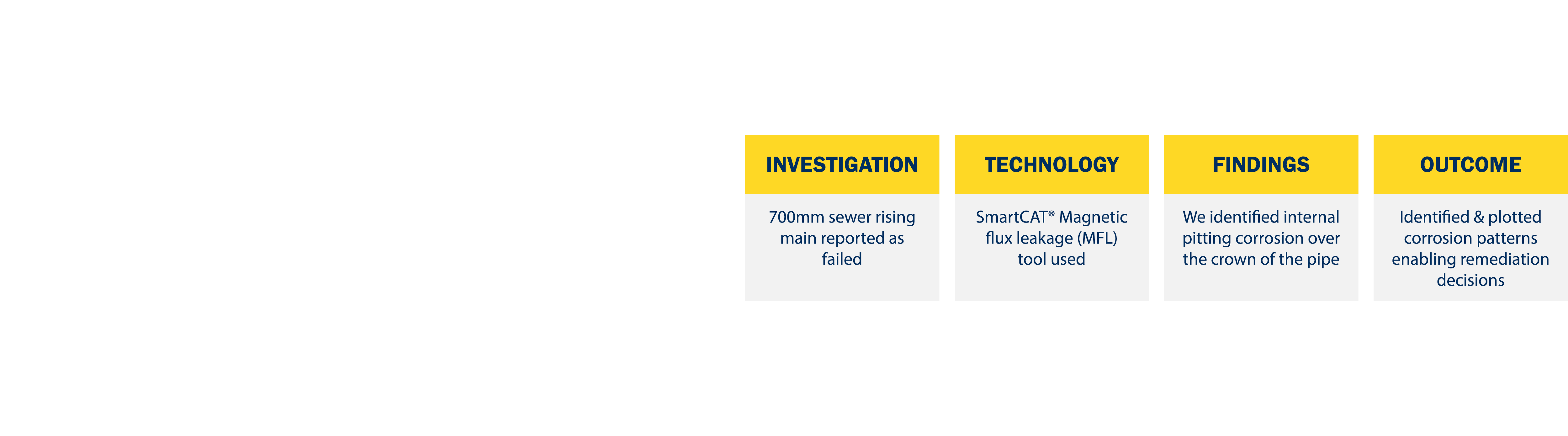

SmartCAT®, our patented water pipeline condition assessment technology, enables rapid non-intrusive assessment of the condition of metallic pipes.

Pipelines of 300mm diameter and above can be inspected using a multiple pass. SmartCAT® scans the pipe along its length in ‘slices’ with the tool being indexed around the circumference after each scan.

Standard pipelines diameters of 75, 100 and 150mm can be inspected in a single pass using SmartCAT® 360. Other sizes can be manufactured to order. The SmartCAT® 360 wrap around feature allows the full circumference to be scanned simultaneously. Used externally on the pipeline to avoid disruption to supply, SmartCAT® induces magnetic flux into the pipe wall and finds locations where flux is displaced due to non-metallic defects. Along with proximity, distance and azimuth sensors, both internal and external defects are identified, measured, and their location recorded.

Unrivalled pipe condition analysis and reporting

- Calculates time to leakage and structural failure

- Helps you make confident decisions on pipe replacement

- Gives statistical predictions for uninspected sections

SmartCAT® gives detailed information on the extent of corrosion pitting on both inner and outer pipe walls. This is critical to understand as individual corrosion pits can grow sufficiently deep to cause through-wall leakage and, importantly, can initiate fracture.

Analysed results show and allow the sizing of pipe wall corrosion defects which are then imaged across the full-inspected pipe wall area and used to statistically predict corrosion patterns in uninspected pipeline sections. This means the likelihood of leakage, fracture and bending failure can all be calculated.

As well as finding and sizing pitting defects, SmartCAT® also shows other corrosion patterns. For example, internal corrosion grooves as seen in sewer rising mains.

Get a quote!

For more information on SmartCAT® contact us on 01670 739999.